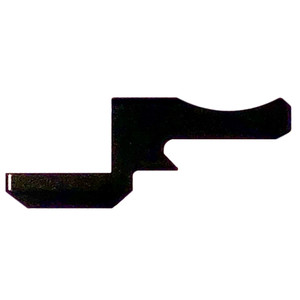

LRA Palma Sight Side Mount 1/4 MOA Match Rifle Direction

Long Range ArmsLRA Palma Sight Side Mount 1/4 MOA Match Rifle Direction

The LRA Palma Sight is made in Idaho Falls, ID using the highest quality materials and closest tolerances consistent with reliability and long life.

- 1/4 MOA adjustments (per click)

- 3 MOA per revolution both Windage and Elevation

- Hardened and ground stainless steel LH 1/4-32 precision adjustment screws (USA Standard)

- Precision machined and anodized 6061 Body

- Replaceable/refurbish-able precision form threaded brass cartridge for both elevation and windage adjustment screws

Included; LRA Palma Sight, 1 custom captured wing screw (to attach the sight), Storage Case, 4 extra hardened balls, 2 extra springs, .050, 1/6, 5/64 allen wrench's, T8 torxdrive, and Supper Lube oil pen

Attach the sight to the rifle utilizing the supplied wing screw.This should be moderately hand tightened and checked from time to time during use.

Storage- the LRA Palma Sight should be dismounted and stored in the provided case during transit and when not in use.

Maintenance- normal cleaning can be accomplished using compressed air or non sulfuric, polymer safe spray solvents. LRA recommends using Isopropyl alcohol. Re-lubrication is required following cleaning with solvents. Avoid heavy oils.

LRA recommends lightly lubricating the adjustment screws and guide rods with Super Lube Synthetic Lubricant with Syncolon(PTFE) (Oil Pen applicator part number 51010). Standard Super Lube Synthetic Oil works well and should be used sparingly. Use compressed air to remove excess lubricant. Do not use sulfur based oils.

Adjusting/Removing Turrets- Each turret knob holds two springs and two balls that will become free when removing the turrets. Hold pressure on top while loosening the screws attaching the. (Supplied .05 wrench for the elevation turret and supplied 5/64 for the windage turret). If you choose to remove the turret, re-lubricate the springs and balls with grease. Assembly is much easier when a small amount of grease is placed upon both ends of the spring, insert the springs into the turret, place balls on top of springs and place the sight screw onto the turret. (We use and suggest Super Lube synthetic grease 21010 1/2 oz tube)

Gapping the Turrets- hold slight pressure on the turret, loosen screw holding the turret, slide a piece of paper between the turret and detent plate on either the 0 or 6 side of the turret to avoid contact with the balls. Hold slight pressure on the turret against the paper, snug attaching screw holding the short end of the supplied wrench, remove paper. Hold the sight up to the light and verify proper clearance, the paper should still be able to slide back into the space.

Torque specs- Allen screws should be moderately torqued while holding the short end of the supplied L handle Allen wrenches to avoid over tightening. The 2 screws holding the scales are #8 Torx drive apply moderate torque using the winged Torx driver supplied. We recommend checking all screws periodically through the year.

RECOMMENDED

-

-

-

-

Sale

Creedmoor Sports Palma Rear Sight Cover

$49.95 $44.95